Problem:

A Brazilian beverage manufacturer needed to dry cans and bottles on three packaging lines to ensure that expiration dates printed on the packages would adhere. Home-made air nozzles, headers made from crimped tubing and pipes with drilled holes were being used. The spray system provided the required drying but used a large volume of costly compressed air.

Solution:

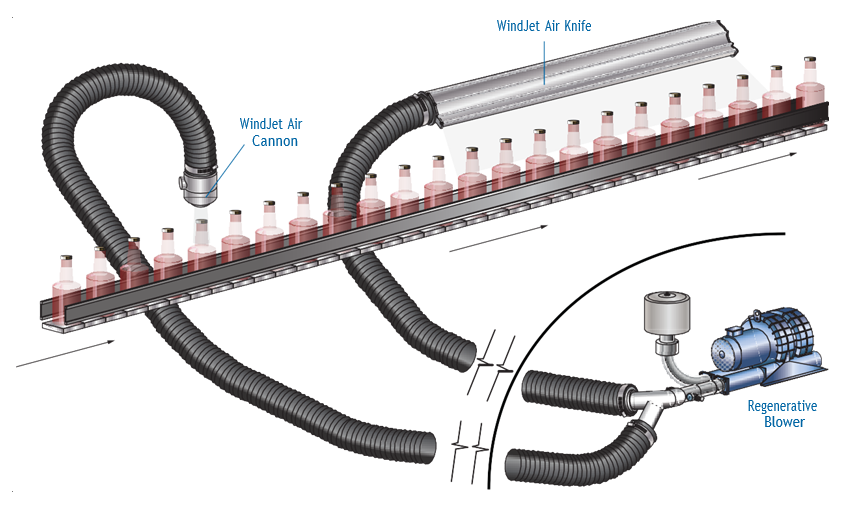

Spraying Systems Co.’s solution consisted of WindJet® Air Knife and Cannon Packages. Each system includes a 15HP blower with a 914 mm (36”) air knife and a 19 mm (3/4”) air cannon which powerfully dry the moisture on the necks and the caps of the bottles.

The WindJet Systems use low-maintenance regenerative blowers to produce clean, heated air. The low noise blowers are extremely energy-efficient. The air knives and air cannons deliver uniform, high-velocity air streams that are spray drying the cans and bottles before printing.

Results:

The customer was spending more than US$200,000 annually to operate the compressed air systems prior to installing the WindJet® systems. The new systems have eliminated the need for compressed air for drying. Monthly savings of more than US$20,000 per month enabled the customer to offset the investment in the three WindJet spray drying systems in about three months.

A Closer Look at the System

WindJet Air Knives produce a uniform, high volume, constant air stream along the entire length of the knife. The spotting and blotching problems associated with many air knives are eliminated.

WindJet air cannons provide a high velocity air stream into holes and indentations to ensure complete drying.

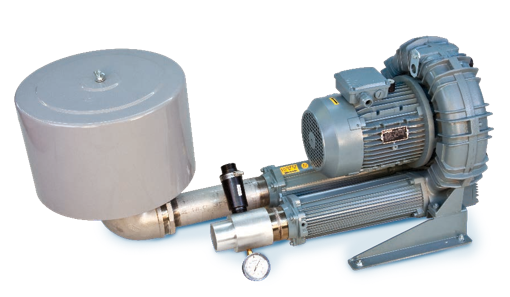

Regenerative blower are rugged, reliable and require infrequent, minimal maintenance. These blowers use a dynamic operating principle that recycles a certain amount of air and provide performance comparable to many multi- stage or positive displacement blowers.